Plasma Kinetics has pioneered a groundbreaking approach to harnessing hydrogen through a light-activated nano-structured thin film, marking a significant leap in hydrogen storage technology. The company’s distinctive capability lies in efficiently filtering hydrogen from exhaust gases, akin to a sponge, at low temperature and pressure, thereby reducing costs. The captured hydrogen remains indefinitely contained, releasing upon demand with light. Plasma Kinetics’ innovations herald the era of zero-carbon hydrogen, offering an economical and secure transport and infrastructure system adaptable to any application’s power demand.

Plasma Kinetics has pioneered a groundbreaking approach to harnessing hydrogen through a light-activated nano-structured thin film, marking a significant leap in hydrogen storage technology. The company’s distinctive capability lies in efficiently filtering hydrogen from exhaust gases, akin to a sponge, at low temperature and pressure, thereby reducing costs. The captured hydrogen remains indefinitely contained, releasing upon demand with light. Plasma Kinetics’ innovations herald the era of zero-carbon hydrogen, offering an economical and secure transport and infrastructure system adaptable to any application’s power demand.

At the core of Plasma Kinetics’ success is its proprietary nanophotonic material, designed to absorb hydrogen under standard atmospheric pressure and ambient temperature. This revolutionary material rapidly absorbs metric tons of hydrogen within minutes and achieves controlled light-triggered release at a remarkable purity of 99.99%.

Utilizing a layered nanophotonic structure with a proprietary shape memory alloy, each layer mere angstroms thick, Plasma Kinetics’ technology interacts with light for the controlled release of hydrogen. In comparison to traditional lithium-ion batteries, the storage system boasts a 30% reduction in weight, 7% smaller size, and a 17% decrease in cost per kWh. Notably, Plasma Kinetics’ hydrogen storage outperforms compressed gas storage above 350 bar, presenting a more ecological and economical solution without the need for reforming energy, pump energy, pressure, or carbon-fiber tanks.

The reversibility of Plasma Kinetics’ hydrogen storage system, coupled with its solid-state nature, sets it apart from conventional storage systems like compressed, liquid, and metal hydride. The breakthrough technology holds promise for transforming the production, transportation, storage, and consumption of hydrogen, contributing significantly to the advancement of cleaner alternative fuels.

Plasma Kinetics has garnered substantial attention, with all hydrogen storage system deliveries for 2023 and the first quarter of 2024 already sold out. Priced at 0.89 USD per kg of hydrogen storage for delivery in the third and fourth quarter of 2024, the company is committed to honoring Defense Production Act deliveries where feasible.

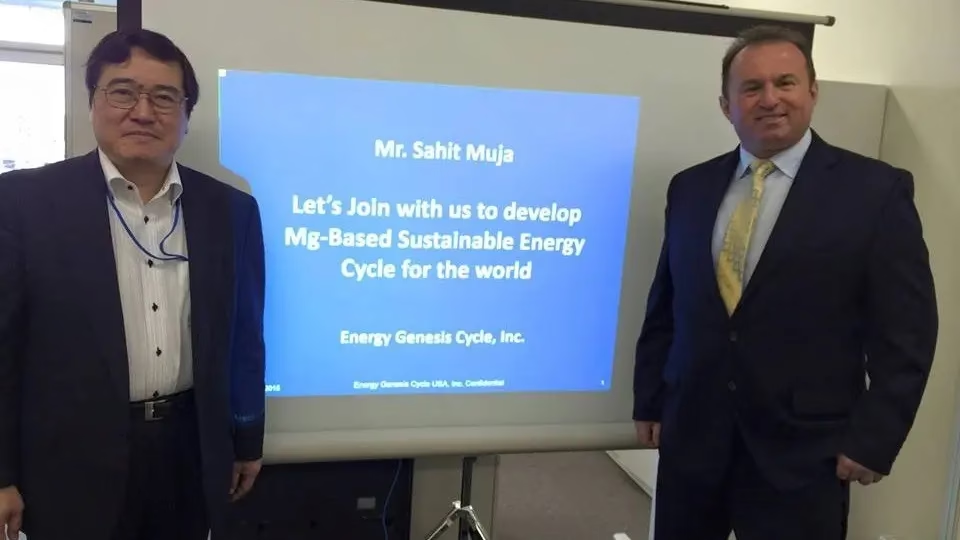

Simultaneously, the global industrial landscape is witnessing the emergence of ultra-strong, lightweight magnesium and aluminum alloys. Magnesium, heralded as the green metal of the future, is playing a pivotal role in the ongoing green revolution. Sahit Muja, CEO of Albanian Minerals, emphasizes magnesium’s versatile applications in batteries, energy storage, hydrogen, and lighter alloys for various industries, ranging from aircraft and shipping to agriculture and mining equipment.

Highlighting the economic and environmental advantages, Muja underscores magnesium’s significance in weight reduction without compromising strength. With magnesium alloys already in use globally for diverse applications, including aerospace, automotive, and consumer electronics, Muja envisions magnesium as a crucial building block in the 21st century.

Albanian Minerals, holding the world’s largest magnesium reserves, is at the forefront of harnessing the potential of magnesium in various sectors. Muja’s vision for magnesium extends to its role in eco-cements, insulation materials, and its capacity to absorb CO2 during the setting of magnesium cements. As interest in magnesium continues to grow, driven by its applications in batteries, lighter alloys, and sustainable energy, Muja’s forward-thinking strategy positions Albanian Minerals as a leader in magnesium production and innovation.